|

||||

|

What we do...

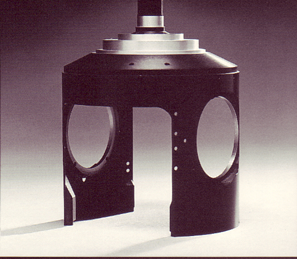

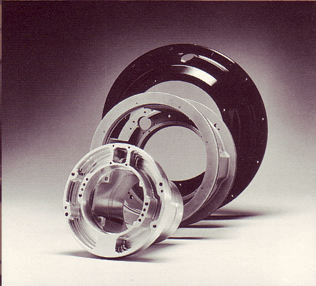

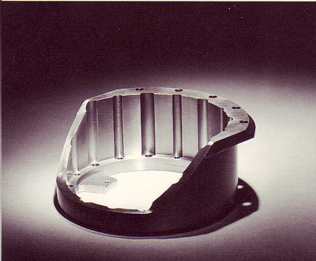

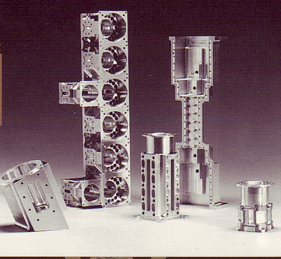

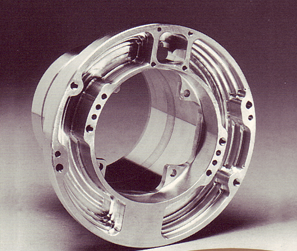

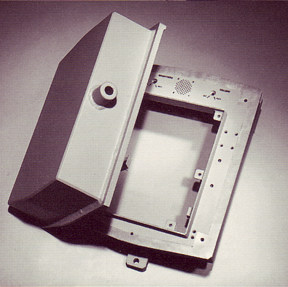

The precision that is engineered into the machining of our components ensures the reliability of our customer's product. Today's trends in client inventory reduction, the rationalization of production and procurement resources and reliable source inspection procedures, have fostered an interactive client/customer relationship. As a result, "Ship To Stock" is the norm rather than an exception. Clean Room assembly and test facilities are available to be custom equipped by contract or by customer specification, to allow assembly and/or testing of machine components, procured hardware and proprietary components to client specifications.

Full inspection, assembly, identification custom packaging are an integral part of our commitment to client satisfaction. Bonded storage areas are available for inventory control ready to be shipped and integrated by the client from a single dedicated source.

ROSTAR’s technical expertise lies in a skilled team of process planners, programmers, inspectors, machinists and toolmakers whose capabilities are kept current through our on going in-house training programs.

|

To ensure quality consistency and adherence to customer and national quality standards and specifications, a fully integrated centralized computer system is in place to control every stage of the manufacturing process. This includes: Process Planning, Procurement of Certified Materials, Real Time Scheduling, Document Control, Inspection and Test, and all aspects of the manufacturing process. Traceability at each operation function ensures adherence to procedures, monitoring of schedules and machine loading.

To ensure quality consistency and adherence to customer and national quality standards and specifications, a fully integrated centralized computer system is in place to control every stage of the manufacturing process. This includes: Process Planning, Procurement of Certified Materials, Real Time Scheduling, Document Control, Inspection and Test, and all aspects of the manufacturing process. Traceability at each operation function ensures adherence to procedures, monitoring of schedules and machine loading.